Sustainability

Environmental Protection

We understand that our impact extends beyond our own operations to the different stages of our value chain. Therefore, we have implemented rigorous supply chain management measures aiming to minimise our environmental footprint, promote social welfare, and ultimately drive sustainable development along the value chain. We seek to partner with suppliers who demonstrate a share our commitment to responsible practices, and encourage their continuous improvement.

Promoting Green Product Innovations

Green materials and sustainable design along the value chain

The sustainability of product starts from the design of the product, therefore we take practical steps to incorporate environmental considerations into our sportswear products. To achieve our goal of minimising the environmental impact of our products, we focus not on our own manufacturing activities, but also the material selection and end-of life disposal.

In terms of raw material, we have continued to steadily increase the use of environmentally friendly materials in our products and address the environment impact of material used. For example, the production of natural fibres that are key to our clothing productions could be resource-intensive, and may lead to various environmental pollutions and health implications. Therefore we are actively pursuing the use green alternatives, such as organic cotton, recycled plant materials, and biodegradable materials to produce our clothing and footwear products. Below are some examples of green materials and their latest application in our products:

Besides green materials, we also incorporate green design concepts into our products. For example, we made various components of our footwear detachable so that customers can easily recycle the components instead of direct disposal, reducing the end-of-life environmental footprint of products.

Advocating sustainable consumption

We are dedicated to enhancing the sustainability of our sportswear by actively exploring the use of various recyclable and bio-based materials in our products. To provide consumers with more sustainable options, we are introducing new eco-friendly products every season.

In 2023, Xtep developed 11 eco-conscious shoe products, with 5 in the sports category including our flagship competitive running shoes and 6 in the lifestyle category. We successfully transformed bio-based eco-products from concept to mass production, especially in our leading competitive running shoes, achieving a leap from eco-friendly concepts to performance. We are glad to see that consumers responded positively to the green materials and design concepts of our products, and will stay committed in development more eco-friendly products for consumers.

Preserving The Natural Environment

As a company in the sportswear industry, we are continually working to advance sustainability across our operations and product portfolio. By instituting programmes in our facilities to enhance energy efficiency, reduce waste, and lower emissions, we aimed to design apparel and sportswear with lower environmental impacts over their lifecycles. Through exploring innovative product designs and sustainable operation initiatives, we strive to operate responsibly in a way that aligns with our customers’ growing interest in brands that protect the environment.

Our Environmental Management System, which is certified under ISO 14001, provides a structured framework for monitoring the environmental performance of our daily operations and ensuring full compliance with increasingly stringent environmental regulations. To guide our sustainability efforts, we have defined focus areas and targets for preserving the environment. For details, please refer to the “10-Year Sustainability Plan” in the “Our Sustainability Framework and Initiatives” section.

Tackling Climate Change

Climate-related risks and opportunities

Preserving The Natural Environment As a sportswear manufacturer, the Group recognises the importance of confronting risks posed by climate change. We continue to evaluate and implement various climate risk management initiatives to stay vigilant in addressing climate related impacts and risks across our business.

Physical risks such as rising global temperatures, altering worldwide climate patterns, and more frequent severe weather events have the potential to impact our operations by disrupting supply chains and reducing infrastructure resilience. Transition risks from policy changes and market preference shifts could also considerably affect operations. For instance, the global transition to low-carbon economies may increase our production costs by investing in sustainable energy. However, these risks also bring opportunities by developing new technologies and products in response to climate change.

Energy efficiency and carbon reduction

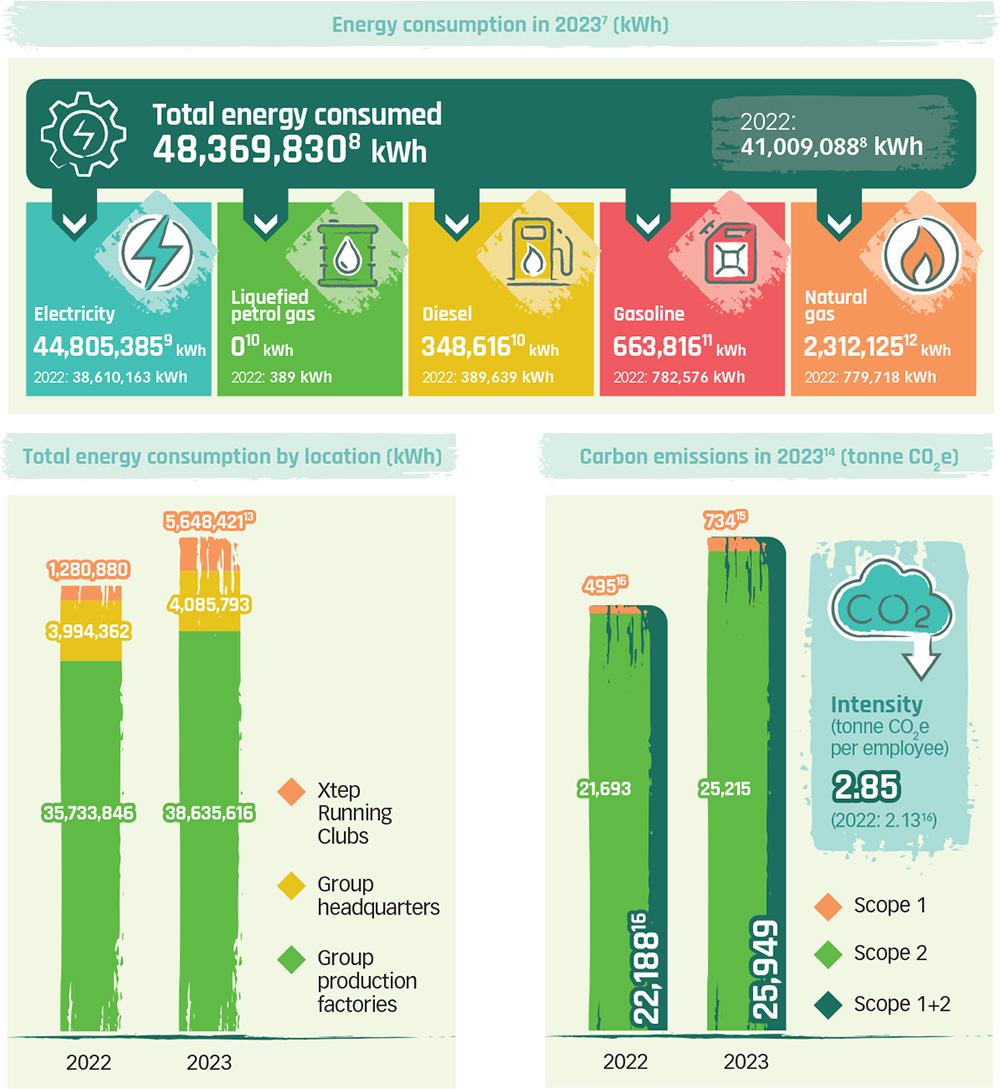

The Group is committed to reducing our carbon footprint by strengthening energy management and supporting the transition to a low-carbon future. We have established four targets for responsible energy use and work on various initiatives as part of our ongoing efforts to progress these targets.

We made efforts to adopt cleaner energy at our production facilities. At our Hunan factory, we have installed a solar photovoltaic system with the aim of decreasing reliance on purchased electricity from the grid while positioning us to evaluate expanding onsite renewable generation to other sites. At our Shishi factory, we have begun planning for the implementation of a solar utilisation plan to evaluate approaches to leveraging solar power generation at the site.

Continuous upgrades of our existing facilities help enhance the energy efficiency of our operations. We replaced lighting fixtures throughout our factories with LED alternatives and integrated motion-sensor lighting controls in onsite dormitories. The dormitory water heating system was upgraded to a smart energy hot water device that utilises heat pump technology powered by electricity for greater energy efficiency. All boilers across our production sites are powered by natural gas, enhancing energy efficiency and reducing air pollution and greenhouse gas emissions. Regular maintenance is conducted on the boilers to minimise any potential wastage of resources from ageing equipment or failures.

Fostering a culture of energy conservation across our operations is an important part of strengthening energy management. At our branded stores, factories, and headquarters, guidance on energy-saving practices and internal communication materials are prominently displayed, providing information about how daily practices can support energy conservation. In addition, we closely monitor electricity consumption at all of our operations to promptly identify any abnormalities in energy usage and continually enhance efficiency.

Air Emission

In our production process, the combustion of fuels for equipment such as boilers inevitably results in certain air emissions. We have switched to powering our boilers with cleaner natural gas rather than diesel, resulting in lower air emissions and improving thermal efficiency. In addition, exhaust gases from our production processes are treated with activated carbon to remove pollutants before being released into the atmosphere, which are replaced on an annual basis by qualified vendors.

Palladium and K·SWISS upgraded the exhaust gas collection hood of the waste gas treatment system, ensuring optimal and consistent performance of the treatment facilities. Moreover, we are considering developing an energy data reporting system to enable standardised emissions data collection and calculation processes, which can improve data accuracy and create a more robust air emission management system.

Water Management

Water Usage

Most of the Group’s water consumption occurs during the production process and its dormitories. To improve water efficiency in these areas, we have implemented various process improvements and water recycling and reuse measures to minimise water usage. Regular inspection and maintenance of our plumbing infrastructure ensure reliable operation of the system and avoid wastage of water resources due to equipment failure. We have also adjusted the water pressure of our living quarters and installed timers to control the flushing frequency of the washrooms in our factories and dormitories, which reduces the overall water consumption.

Apart from the process and infrastructure improvements, we are also working on cultivating a culture of water conservation among employees. We have launched education and awareness campaigns to raise awareness among our employees on the significance of water sources and encourage practices that can reduce daily water consumption.

Wastewater discharge

Our wastewater discharge is not subject to specific requirements from the government as it is domestic effluent with insignificant chemicals. We discharge such sewage into the municipal wastewater network in compliance with local regulations in all our operations.

Use of Chemicals

As a responsible sportswear producer, the Group is committed to ensuring our product safety and minimising the use of hazardous chemicals. We fully comply with our internal standards and applicable national regulations regarding chemical usage in all our operations.

We have been researching safer alternatives and reducing the use of chemicals that are of concern in our products. Merrell cooperated with Bluesign dyeing auxiliaries’ manufacturers for 80% of its garment production and aims to exceed the high percentage by 2025. Saucony also increased its adoption of fluorine-free water-repellent garments to 10%, with its target of 40% by 2050.

Employee training on proper chemical handling is also a crucial aspect of our operation. Palladium and K·SWISS provide rigorous training sessions to ensure employees are aware of safety chemical management. In addition, we are targeting to increase the use of water-based adhesives, as a safer and less-polluting option, for over 50% of shoe production under our core Xtep brand while maintaining high quality. The proportion of returns and exchanges related to ineffective glueing decreased from 0.079% in 2022 to 0.057% in 2023, demonstrating our efforts to optimise adhesive use and reduce quality issues.

Packaging Material and Waste Management

We have been taking steps to introduce more sustainable packaging options across our brands to reduce the associated environmental impacts. For our core Xtep brand, we replaced tags and quality labels on apparel and accessories with more eco-friendly materials since 2020. We also provide shoe boxes with carrying handles to reduce the use of plastic retail bags. In 2022, 95% of wrapping paper from K·SWISS and Palladium was FSC-certified. From 2023, all inner boxes for product orders of Saucony and Merrell will adopt environmentally friendly material.

The Group is cautious about managing our waste and proper disposal. Hazardous waste from our production, such as activated carbon and contaminated containers, is collected by qualified third parties for disposal in accordance with local laws and regulations. A considerable amount of general waste is generated at our on-site employee accommodations. We uphold the principles of reducing, reusing, and recycling across the living and manufacturing facilities. Recyclable waste is categorised and recycled centrally, and external contractors are appointed to collect and properly dispose of non-recyclable general waste.

7 Energy conversion factors are referenced from the United Kingdom Department for Energy Security and Net Zero conversion factors 2023.

8 This year, we have expanded the our reporting scope of energy consumption to add in the Group headquarters, Xtep Running Clubs (excluding franchised stores), and 2 logistic centres in Nan’an and in Cizao. To ensure consistency and comparability, the 2022 total energy consumption and breakdown by fuel types have also been revised in line with update on the energy consumption data in 2023.

9 The total electricity consumption decreased compared to 2022. This was due to the increase in production volume and extended working hours at our Fujian Quanzhou Koling factory and Fujian Shishi factory, as well as the installation of new air-conditioning units in the office area at our Fujian Shishi factory.

10 The total amount of liquefied petrol gas consumption dropped to 0 in 2023, as our Fujian Jinjiang main factory which uses liquefied petrol gas for cooking had ceased operation in December 2022.

11 The total amount of diesel and gasoline consumption decreased in 2023 due to the reduction in the number of vehicles in our Fujian Quanzhou Koling factory and Fujian Quanzhou main factory.

12 The total consumption of natural gas increased significantly compared to 2022. This change was primarily attributed to the higher number of employees dining at the cafeteria in our Fujian Shishi factory and the expansion of cafeteria services at our Fujian Quanzhou main factory, both of which use natural gas for cooking.

13 The expansion of floor areas in several stores contributed to increased energy consumption in 2023. Additionally, a significant number of stores, which were closed in 2022 due to COVID-19, resumed full-year operations in 2023, marking the first year without the pandemic’s operational impact.

14 Emission factors are referenced from the Guide to Calculating and Reporting Greenhouse Gas Emission in Industry and Other Sectors (Trial) issued by the National Development and Reform Commission of the People’s Republic of China and the average emission factor of the national grid in 2022 announced by the Ministry of Ecology and Environment of the PRC.

15 Scope 1 emission has increased significantly in 2023 due to increased consumption of natural gas in our Fujian Quanzhou main factory.

16 Revised according to the restated 2022 scope 1 emissions.

17 The reduction in overall water consumption was mainly due to the water efficiency improvements, including the flushing system upgrades.

18 In 2023, the gradual replacement of plastic strips with plastic tapes led to a decrease in strip usage and an increase in tape usage compared to 2022.